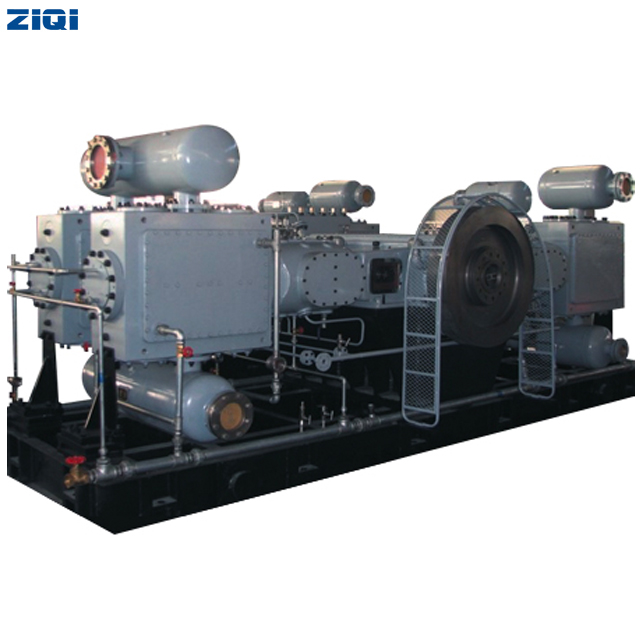

Powerful Ethylene Compressor for Industrial Processing

Product description

Reciprocating Gas Compressor is a volumetric compressor, it has the characteristics of wide range of exhaust pressure, exhaust volume and high volumetric efficiency. It is widely used in many industries such as hydrogen -making, petrochemical, silicon, fluoride chemical, metallurgy,and so on. Our company conducts professional customization for the actual working conditions of customers, providing compressor products that fully meet the actual needs on the spot.Product type: It has a variety of models of M -type, D -type, L -type, and P -type, and more than 60 product series. The compressor stage can achieve pressure matching from one to six, fully covering the market demand.

Product features: large displacement, low speed, meet the API618 standard.

Product parameters

| Parameters of Gas Compressors | |||||||||

| Piston Force KN | 800 | 500 | 320 | 250 | 160 | 100 | 65 | 45 | 30 |

| Compressed gases | Hydrogen, nitrogen, natural gas, ethylene, propylene, coal gas, hydrogen chloride, hydrogen fluoride,carbon dioxide, chloromethane, carbon monoxide, acetylene ammonia, difluoromethane,Tetrafluoroethene, pentafluoroethane, hexafluoropropene, etc. | ||||||||

| Discharge pressure MPa(G) | ≤25 | ≤30 | |||||||

| Compression level | 1-4 | 1-6 | 1-3 | ||||||

| Number of columns | 2-4 | 2-6 | 1-4 | ||||||

| Layout form | M/D | M/D | M/D | M/D | M/D | M/D/P | M/D/P | M/D/L/P | L/P |

| Distance of run mm | 280-360 | 240-320 | 180-240 | 200 | |||||

| Rotary speed rpm | 300-375 | 333-450 | 375-585 | 420-485 | |||||

| Maximum motor power KW | 5600 | 3600 | 3300 | 2700 | 1250 | 800 | 560 | 250 | 75 |

| Skid-mounted | Non-skid-mounted | Non-skid-mounted/Skid-mounted | Skid-mounted | ||||||

| Digital analog design | Yes | ||||||||

| Pulsation calculation | Yes | ||||||||

| Process inspection | According to the quality plan, we conduct chemical composition, mechanical properties, flaw detection,water pressure test, and air tightness test on each main component. | ||||||||

| Factory inspection | We conduct no-load mechanical operation test according to the quality plan. | ||||||||

| On site acceptance | The compressor operates under actual work conditions and we conduct 72-hour assessment and acceptance. | ||||||||

| Application industry | Hydrogen, silicon, chlorine, petrochemical, metallurgical, pharmaceutical, aerospace, nuclear power, etc. | ||||||||

Products

Products